Detect and locate leaks down to 1 · 10–4 mbar · l/s using ultrasonic leak testing

MACEAS’ ultrasonic leak testing provides accurate leak detection and localisation at minimal operating costs, making it ideal for automated processes. Take advantage of this low-maintenance solution to increase the efficiency and quality of your manufacturing process and quality assurance.

Your benefits at a glance:

- Objective, transparent leak testing

- Several parts can be tested in one basin

- Direct, localising measurement method

- Low test gas costs thanks to use of air or nitrogen as test gas

- Semi-automatic or fully automatic leak testing systems

- Low-maintenance ultrasonic system

- No periodic calibration required

- No vacuum components necessary

- Low operating costs

- Product holder for other product variants

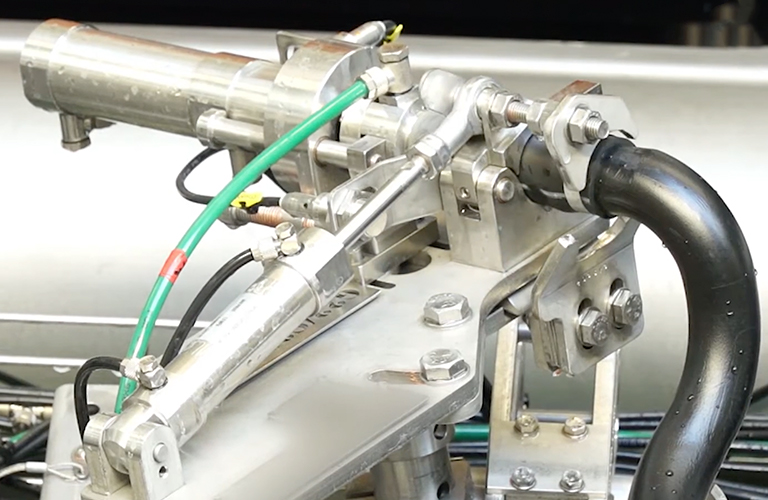

Visualization of ultrasonic gas bubble detection in the water bath

Ultrasonic Leak Test

Ultrasonic leak testing enables precise and reliable detection of gas bubbles in a water bath. This worker-independent and automated process minimizes human error and increases efficiency even with small leak rates.

Applications

Not only the automotive industry has special quality requirements for its products, but other industries also manufacture products that place high demands on a corresponding tightness. Among other things, the leak test of hot cylinders (boilers) from the heating, building, water management and energy sectors should be mentioned here.

Unique: leak testing and leak location quickly and reliably using ultrasonic gas bubble detection in a water bath. The integration of a strength and pressure test as an additional quality assurance feature.

Due to the strict requirements for the hydrocarbon emission values of fuel tanks, the ultrasonic leak test plays a central role in the quality control of fuel tanks. The specifications are becoming increasingly strict. With the optional ultrasonic gas bubble detection, the leak can not only be detected, but also localized.

Not only do fuel tanks have to be checked and tested for leaks in the automotive sector, but also filler pipes. This can easily be done using ultrasound, even with a combination of fuel tank and filler pipe. Leak testing by means of an ultrasonic leak test is a proven and reliable quality control method.